Categories

The danger of dental aerosol is now addressed in many studies and technical treaties both Italian and international. In Italy and all over the world dentists and other professionals are facing the “phase two” of the Coronavirus emergency, which provides for a partial relaxation of containment measures with the reopening of some professional activities. However, the risk of infection by potentially infected dental aerosols remains and has come to the fore with this pandemic despite the long-known exposure of dentists to countless microbes, since the sixties with outbreaks of hepatitis B virus or in the following decades with the problems of possible HIV transmission. The aspiration of the dental aerosol in the area between the patient and the operator will therefore henceforth be good practice to be applied in dental practices to drastically reduce the dispersion of particles carrying pathogens into the air, before they disperse in the studio when it would be impossible to intervene except by aerating the premises.

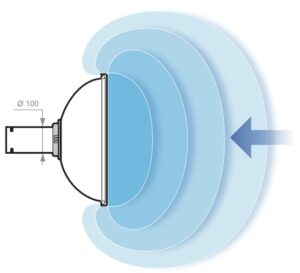

| Technically this means to have appropriate devices to suck the particles of dental aerosol at the source and to do this there are no other solutions than a professional extractor equipped with a self-supporting suction arm, to be placed with the hood so that the air flow intercepts the particles before they reach the respiratory tract (protected by PPE) or other parts sensitive to infection. The suction hood, if well designed and equipped with a sufficient flow rate of at least 400mc/h, creates a dental aerosol collection “sphere” with dimensions like its nominal diameter as you can see in the graphic on the right. Our Engineers estimate in diameter 350mm the minimum size that should have a suction hood for dental aerosol, so you can work at least 30cm from it.

They are already present on the market dental aerosol extractors in mobile version with these characteristics such as, for example, the VS400M by Secureair®, but although very compact they are in any case an additional footprint within the studio, sometimes unsustainable for the few spaces around the assembled.

|

|

Dental aerosol suction system, centralized technical solution

In the case of dental practices or dental clinics with several rooms to equip the solution of the central suction system for dental aerosols becomes very interesting because it is characterized by some important advantages:

- No footprint on the ground around the dental unit

- Suction arm fixed to the wall or ceiling, customizable in length

- Suction arm foldable when not in use

- Single suction unit outside the operating zones

The dental aerosol suction system should be designed and sized just like an industrial suction system, using common technical parameters regarding the performance of collection of the hoods, but customized according to the characteristics of the dental office, with reference to:

- Number of workstations to be served simultaneously

- Type and availability of internal passages for connecting pipes

- Room heights, type of masonry and ceilings for fixtures

What are the key components of a dental aerosol suction plant

As for any suction system, even the one inside a dental practice to be usable over time efficiently and reliably must certainly be designed according to precise engineering parameters but must above all use technical articles designed and built for this application, with reference to the suction arms and suction unit.

| The suction arm for dental aerosol is of fundamental importance that it is of high quality, but above all designed and built for laboratory or medical applications, because it will be the object of the suction plant you will handle every day, resulting in continuous cleaning and sanitization.

The pipes and components must be made of aluminum or of signifiable plastic material, to avoid those with metal components, visible springs, or other ferrous objects. In addition, the ideal pipe diameter is 100mm inside, to facilitate suction and reduce noise. For our dental aerosol suction systems, the technicians exclusively use this type of suction arm, in the version distributed by Secureair® in various lengths and with different hoods available. |

|

| The suction unit to which the pipes coming from the suction arms will be connected, in the case of the dental aerosol suction system is designed for maximum performance with minimum encumbrance especially on the ground, so that it can be easily installed on balconies, terraces or in technical rooms normally used for equipment.

The suction flow and pressure are dimensioned in three different models to be able to suck the dental aerosol with efficiency in case of simultaneous suction by 2, 4, or even 8 arms. The type of filtration is the specific one developed by Secureair® for the problems related to Covid-19: Stage 1 Coalescence Fluid Abatement Pre-chamber |

|

The risk of the dental aerosol and the possible solutions have already been anticipated by the technicians of the division Secureair ³ with this article that we suggest you read to deepen the suction techniques, all with the common objective of sucking at the source and shoot down through the filters the Coronavirus particles estimated by experts with dimensions between 0.12 and 0.16 µm.

Our consultants are available for more information or to develop a dedicated plant proposal please contact us for more information.