Categories

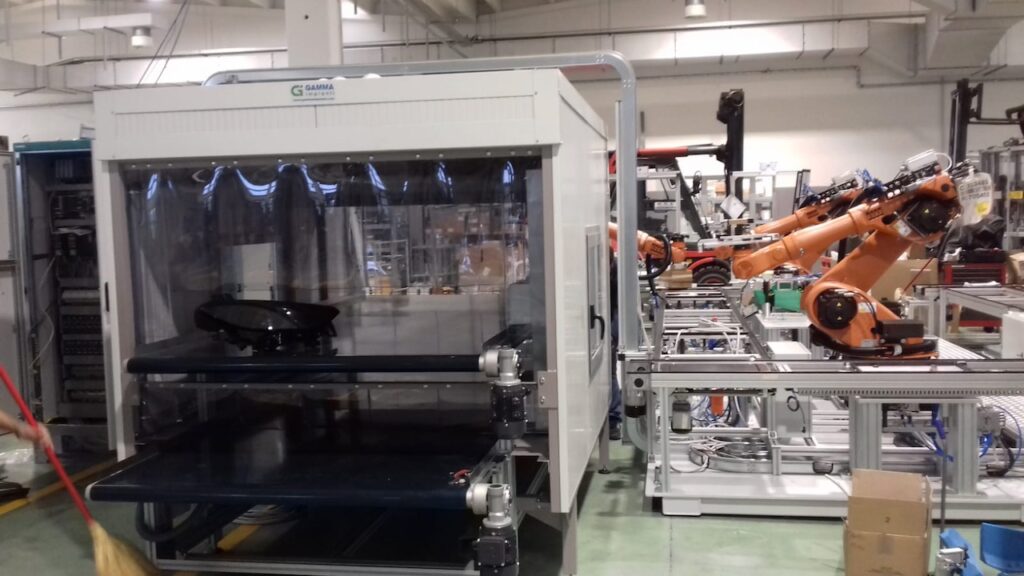

The robot suction systems represent the latest evolution of air suction and treatment systems in industrial and production contexts, with very different needs compared to classic suction systems where operators are involved in the process.

The fundamental point is the design phase, which unlike the classic suction systems cannot be based on executive reliefs but must be based on the beginning on the sharing of files in 3D format.

Thanks to the high experience in 3D design our technical team is able to operate on the customer’s STEP file in order to build the suction system completely to measure, both from the dimensional point of view and depending on the required objectives that can vary from the suction to the air treatment by fine filtration, maintenance of humidity or cooling/heating of the parts handled by the robot.

In the case of robots, the design focus is on factors other than the protection of personnel; the air system or treatment system serving a robot island, in fact, usually has the following objectives:

- protection of the external environment from pollutants produced within the work area, usually with lateral and upper containment for protection from fumes, exhalations, lights, and noise.

- maintenance of specific climatic conditions in the working area, especially when robotic systems are at the service of assemblies or bonding to be carried out at controlled temperature and humidity.

- protection of sensors and equipment involved from fumes and dust, circuits, and electronic components do not like oily or other residues.

Normally the robot suction system is dimensioned as follows:

- one or more suction points positioned close to the robot, close to the production of pollutants; for example, hoods or suction/air supply walls

- a set of suction pipes consisting of rigid or flexible channels of small section therefore with need for high crossing speed

- a high-pressure suction and filtration unit, consisting of motor and fan, or a side channel blower

- a set of ducts for the expulsion of filtered air to the external environment.

The pollutants typically treated with suction systems for robot islands are:

- Fine dust

- Fumes

- Painting overspray

- Fumes from gluing

Compliance of industry 4.0 robot suction systems

All suction systems in this segment since 2019 have been designed to comply with the requirements of Industry 4.0, in order to be controlled by computer systems or managed by appropriate sensors and drives. For this specific case the following features have been implemented that allow our interlocutors to access the 50% tax credit on the cost of the plant.