Categories

The question does not have a simple answer, in fact whether it is a continuous production or simple retouching to be carried out at the bottom of the line, liquid or spray painting operations are a very delicate process in the company, which places the entrepreneur or the person responsible for the process in front of three fundamental issues to be addressed:

- Achieve the desired quality respecting the project specifications, both from an aesthetic point of view and in relation to the protection of products.

- Protect the health of the painter, by training him so that he uses all the personal protective devices provided and by making him operate in a properly ventilated and filtered area, such as a painting cabin.

- Comply with environmental regulations regarding emissions into the atmosphere, properly filtering the fumes emitted by liquid paint products and solvents that as we know contain volatile organic compounds COV or SOV.

The risks to peopleApplications such as painting, cleaning and parts washing |

|

Protect yourself with adequate ventilation

Adequate ventilation is the most important part of the solution, in fact, the exhalations must be captured before they can reach the respiration zone of the painter and then must be filtered with a system that includes several filtering stages with a final activated carbon, and then be expelled outside the production premises, respecting the National or Regional regulations for the emission into the atmosphere.

Examples of equipment designed for applications of painting materials in industrial and craft processes

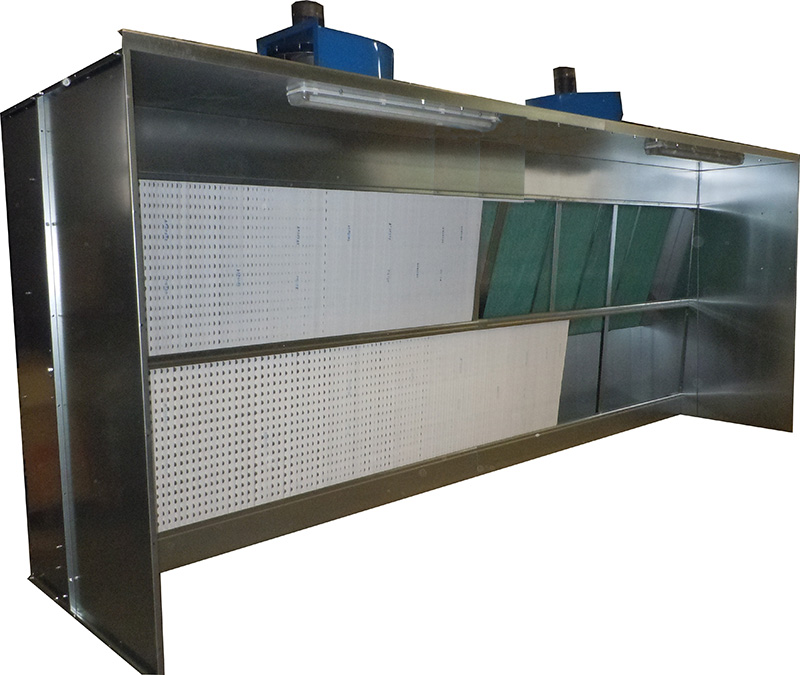

| Industrial open painting cabin or dry suction wall |

Painting cabin with tunnel extensible/compactable cover |

Mini industrial painting cabin dry with shelf |

||

|

|

|

||

| ADVANTAGES – Allows the creation of a painting cabin in enclosed spaces – Low investment and multiple versions available – Lengths from mt 2 to mt 6 , heights up to mt. 3 |

ADVANTAGES – Compactable cover allows loading of workpieces with bridge carriage – When closed it becomes a horizontal flow painting cabin – Customizable in width, height, and length |

ADVANTAGES – Compact – Ideal for small coatings or gluing – With integrated extractor or external line connection |

Contact us for advice or a free quotation, one of our expert is always available.

Technical definitions in liquid metal painting

PRIMER IN POWDER PAINT (PP)

Primer means the first layer of paint or varnish that is applied on a suitably prepared substrate before passing subsequent coats to improve the corrosion resistance of the painting cycle.

PAINTING PRODUCT (PV and PVE)

By painting product is meant a product of organic nature that after application and its polymerization covers the product with a continuous film performing a protective and/ or decorative function of the support. The set of these products with these characteristics must therefore be called “paints and varnishes”, or “painting products”, a term that is often abbreviated to PV.

Painting is carried out by applying one or more paint products depending on the final destination of the product. A typical example with several paint products is the protection of ferrous supports by means of an anti-corrosive primer followed by a finishing primer. This sequence of painting products, used for the painting of any artifact, is called “painting cycle”, or simply “cycle”.

—–

Institutional technical sources and references:

– UNI EN 12215 (2010): Painting systems – Painting cabins for the application of liquid painting products – Safety requirements.