Categories

Fume suction systems to comply with regulations

The smoke extraction systems are of fundamental importance within a professional activity and above all are required from a regulatory point of view in relation to the conformity of the workplace as indicated in Title II of Legislative Decree no. 81/2008 and compliance with the general principles of prevention (regulatory reference: art. 63 paragraph 1, art. 64 paragraph 1 lit. a) – Annex IV – Art. 15 -18 – 224 of Legislative Decree no. 81/08).

In fact, smoke suction systems are among the mandatory adoption of the measures provided for in Annex IV, as they concern minimum requirements of the working environment.

In particular, it is necessary to ensure the general ventilation coordinating it with the local fume suction systems, ensuring the reintegration with the intake of healthy air from outside and avoiding interference between these systems.

The polluting particles released in the workplace are difficult to manage and dangerous for the health of those who breathe them.

Depending on the type of work and the material used, the risks are different, and it is important to identify them both to optimize investments, and to intervene with the most suitable solution for your company.

For a proper self-diagnosis it is essential to ask yourself some questions:

- The ventilation inside my working environment is adequate?

- What kind of materials am I working?

- Are the pieces to be processed covered by solvents or degreasers?

- Is there any air flow I can take advantage of?

- Is it necessary to wear special PPE?

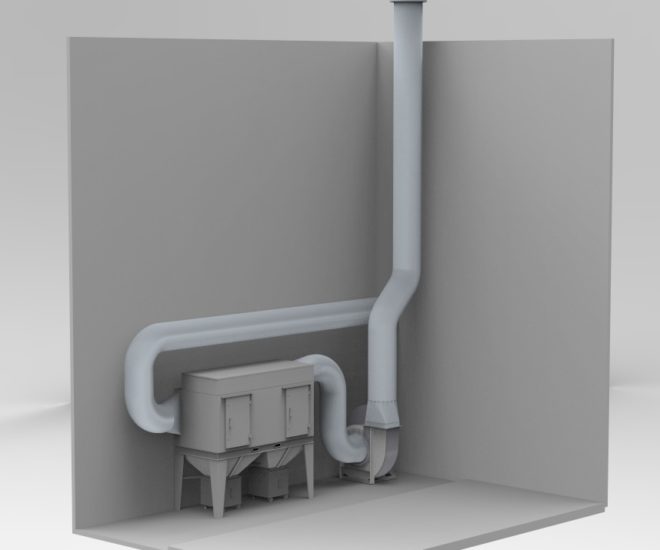

How we design fume suction systems

Our technical office to design a smoke suction system follows a technical path consolidated over the years, a guarantee of result for our customer, divided into several stages:

– the stages of the production cycle in which emissions are present and for which fume suction systems are required are defined. In many cases the problems are not visible but are signaled by smells, dust and fog. When the pollutants have a diameter greater than 10µm, they are visible in concentrations greater than 10 mg/m3.

– together with the production manager or the contact person, we locate the emission point, identifying the type in order to choose the correct point of collection of the suction system in reference to the typical position of the workers; even if the workers are not stationary there, the point at which any evaporation occurs in the solvent environment or other emissions after processing (for example, bonding, painting, welding) should be noted;

– the physical characteristics of the emission (phase, speed, temperature) are defined according to the type of raw and processing material;

– in the case of fume suction or fumes of flammable or explosive chemical agents, we take into account in the design of the suction system of the regulations on the explosive atmospheres (ATEX);

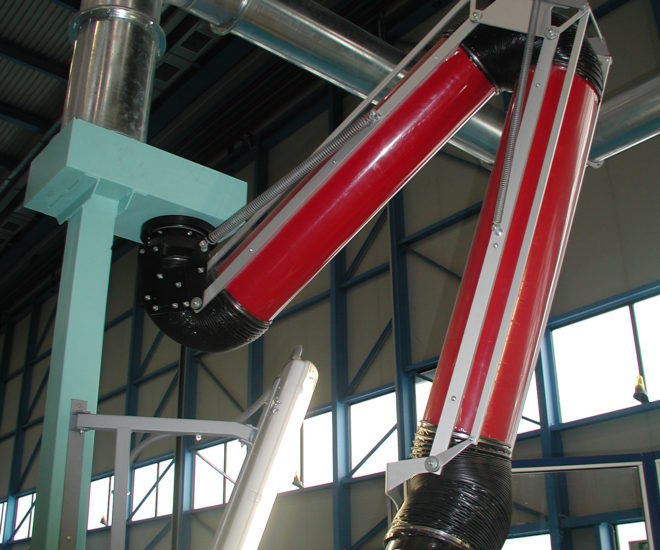

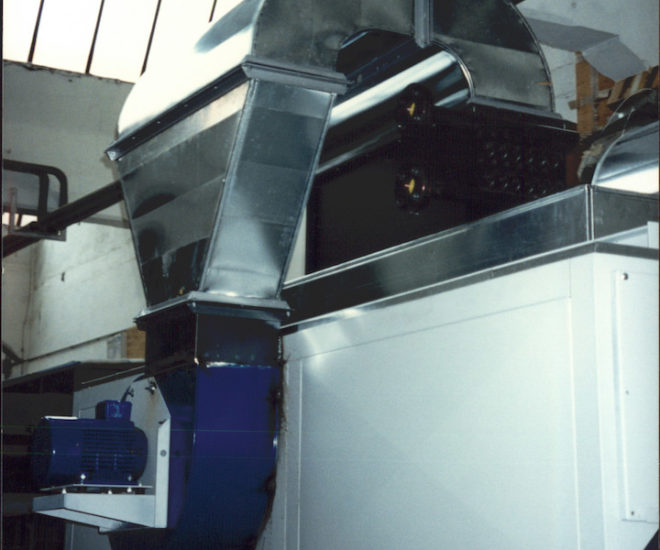

– The most important elements of the suction system, for the purpose of workers’ exposure control, are the hood and the fan: the hood has the task of collecting the pollutant produced at the source, while the fan must create the flowrate and the prevalence necessary for the collection and transport of pollutants outside.

The correct collection in the fume suction systems

In order to correctly capture pollutants, a correct design of hoods and suction systems is essential. The optimum collection rate depends on environmental factors and the type of pollutant. Large particles emitted at high speeds such as those of grinding are more difficult to capture while gas, fumes and particles small and low speed as those of welding more easily follow the movement of air. The hood must be positioned as close as possible to the point of emission and must close as close as possible the point of emission without hindering the production process.

Thefume suction from above is suitable only in case of emissions from hot processes and especially provided that the flow does not intercept the operator’s airways; in this case the hood size must be calculated as a function of the distance between the source and the hood.

Smoke suction systems, air recirculation in ambient

Air recirculation consists in the collection, purification and return to the confined environment of air originally polluted.

In industrial environments, recirculation can only be acceptable for limited and selected processes.

Recirculation shall never be permitted where carcinogenic or suspected carcinogenic or allergenic substances are present in the polluted air, for which no threshold levels are configurable, so that the extraction system must expel outside, after purification if necessary, the pollutants conveyed.

Contact our technical departmentfor advice or an estimate of a fume suction system

Fonts: