Categories

The 2019 Budget Law approved by the Chamber confirms the three rates of increase for the Industry 4.0 suction systems carried out since 1 January 2019.

The percentage of increase in the cost of high digital suction systems has risen to 170% for investments up to 2.5 million euros.

The hyper-depreciation will therefore rise to 270% making the compliance of the suction system to the industry 4.0 standard really important that as already addressed in the past, provides precise requirements not to be underestimated and confused with simple inverter switchboards or other normal filter control equipment.

In fact, the industrial suction and filtration system, in order to enjoy the tax benefits, must be designed using certified systems for monitoring and reporting to project representatives of the status of the various key components, as specified in the list provided by the legislator together with the legislation.

Our technical team in collaboration with leading industry suppliers has already developed for 2017 industry 4.0 suction systems that are perfectly compliant with technical requirements, giving the possibility to its customers to equip themselves together with the suction system with the best monitoring and management technologies and therefore to fully comply with what is necessary to access hyper-depreciation.

Key requirements for industry 4.0 suction systems

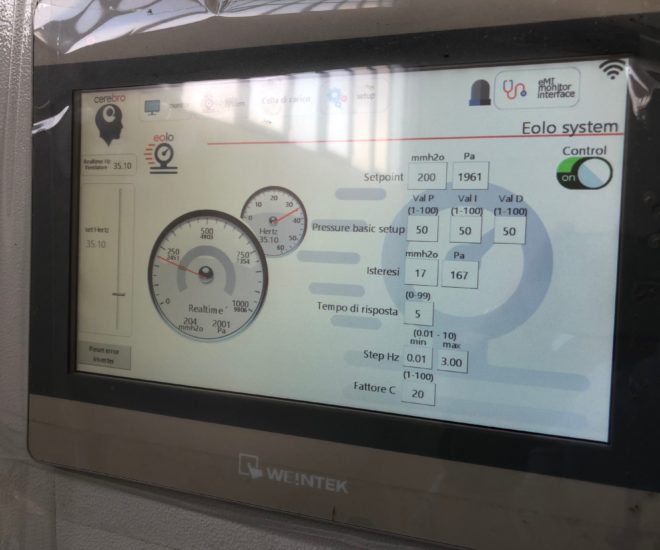

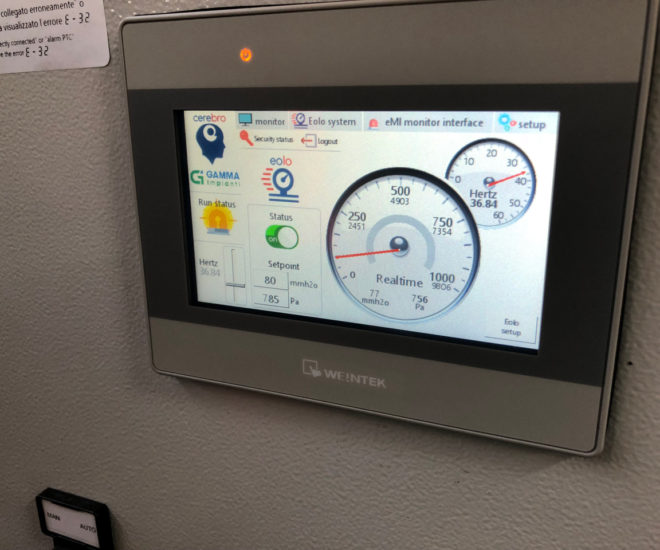

The regulation specifies that hyper-depreciation is intended for capital goods whose operation is controlled by computerized systems or managed by appropriate sensors and drives, for which it is necessary to use hardware and software that can monitor the most important values for the operation of the suction and filtration system i.e:

- Automatic control of the fan revolutions with an inverter, in order to reduce energy absorption in case the system is poorly used

- Control of the degree clogging filters cartridges, sleeves or other, with real-time reporting of the different thresholds and alarm sent by email to the maintenance service

- Remote and optimized management of the automatic cleaning cycles of the cartridge or sleeve filter, with indication of any anomalies

- Control and signalling anomalies or threshold levels of any sensors accompanying the suction system, such as tribo-metric probes, rotovalves, exhaust augers or fire sensors

Which suction systems is it possible to be hyper-depreciated?

From a technical point of view, the basic requirement is that the industry 4.0 suction system is equipped with a series of filters that can constantly monitor the progressive status of soiling.

Consequently, all simple suction systems without filtration are excluded from the benefits but are included:

- Fume and dust extraction systems with metal and pocket filters

- Suction systems with self-cleaning filter cartridges for fumes and micro-dust

- Suction and sleeve filtration systems for large quantities of dust

- Suction and purification system with activated carbon for odors and SOV/COV exhalation

How to make sure you are compliant

The regulation lists a whole series of technical characteristics that the suction systems must possess in order to be facilitated, which means they must be equipped with features such as control by means of CNC (Computer Numerical Control) and/or PLC (Programmable Logic Controller), as well as the interconnection to factory computer systems with remote loading of instructions and/or part program and, in addition, automated integration with the logistics system of the factory or with the supply network and/or with other machines of the production cycle.

Our services for a 4.0 new suction system

- Pre-analysis of the technical needs and investments to be made, in order to correctly set the expenditure and the system according to the characteristics of Industry 4.0

- Technical report and documentation accompanying the use of hyper depreciation, including an EURISP certification to be held in the company for any tax checks

Contact us for further information or to request a quotation.