Categories

Welding fumes: in Italy, according to the latest Istat survey, more than one million of welders work full-time and a large number of workers who occasionally perform technical welding work are all exposed to various health risks, including welding fumes, dust, vapours, and gases

It is known that during the process of welding metals, depending on the technique used, welding fumes, dust and gases containing dozens of different chemical and harmful substances are generated, produced from the same processed material that remains suspended in the air in the form of metal particles or metal derivatives (for example oxides), fillers (electrodes, rod electrodes, lead, welding powder, etc.) or these are removed from the recoating as paints, coverings and detergents.

How much welding smoke does each different process generate?

The amount of fumes generated and their danger depend on different variables, all well known by every expert welder:

- The electrode type, wire diameter, gas flow rate and its composition;

- Obviously the welding technique adopted and its technical setups such as intensity and voltage;

- The type of coating, the thickness and composition and very often the presence of substances that cover the sheet metals.

The health risk is particularly high when welding stainless steels due to the presence of certain transition metals, such as chromium, nickel, molybdenum and manganese, which produce in welding fumes metals and oxidised compounds which are very dangerous for health.

Effective suction depending on the type of work

All the risks outlined above can be drastically reduced by using the right suction and filtration systems when needed. Every experienced welder knows that the most efficient way to control welding fumes is to capture them at the source, as close as possible to the emission source before they pass through the breathing zone of the workers or disperse into the working environment, as seen in the video below:

These techniques of extraction of welding fumes, among other things, require air flow rates much lower than the general ventilation of the premises with consequent lower operating costs even if with higher initial investment costs. Local ventilation must be considered a priority in all cases and in particular when dangerous pollutants are emitted in significant quantities.

The calculation of the necessary flow rates, for the various types of local suction systems, must be carried out considering the correct collection speeds at the source otherwise the system will be ineffective.

The choice of the suction system is made together with our technical department especially according to the size of the pieces and the production needs.

Examples of localized welding fume collection systems

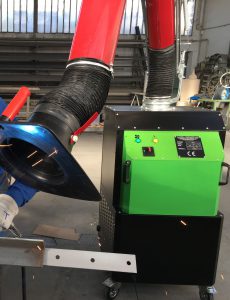

| Suction bench, single or installed in a central system | Suction bench with suction table and retaining walls or suction arm | Portable purifier with HEPA 99.95% filtration and activated carbons | ||

|  |  | ||

| ADVANTAGES – Allows work at undefined workstation – Collection near the source – Reduced flow rate | ADVANTAGES – Collection without the welder intervention – The work plan facilitates operations | ADVANTAGES – Allows several welding points to be reached – Collection near the source – Reduced flow rate |

The welding cabins, equipped with suction wall, are typical examples of systems with not localized collection but that exploit the ventilation of the working area, to be used in case the dimensions of the pieces to be welded make it impossible to use localized systems.

ADVANTAGES

- Effective ventilation

- Collection without the welder intervention

- Excellent insulation of the area

Finally, it is essential to know the application and evaluate your safety needs

Remember that the type of welding fumes suction system, the possible filtration, and personal protection depend on the type of material you are working, welding techniques, and production layout.

Our technical department recommends that you always critically assess your working situation together with the safety officer, asking for:

- Work in limited space with little or no ventilation?

- What kind of metals am I welding?

- Are the parts to be processed clean or stained with chemicals?

- Is my suction system working properly?

- Is there any prevailing air flow that I can take advantage of or that disturbs the suction?

- Should I wear a mask or other personal protective equipment?

The answers to the above questions will lead you in the right direction, which is to improve the working environment while minimizing the risks for all people involved.

Contact us for a free consultation or a quotation.

Sources and references used for this article: