Categories

The extraction of fine and volatile dust from the processing of composite materials is a fundamental aspect for:

- active dust protection from manual processing

- air safety

- the reduction of chemical risk

In fact, the consequences of dust on health should not be underestimated, especially if the exposure time is constant. Workers who are in close contact with dust from composite and acrylic materials must comply with all the rules relating to safety at work, especially those concerning dust-releasing processes.

The first protection is definitely represented by the use of PPE devices or gloves, body protection, and safety glasses, using specific models for silica risk; these measures must be accompanied by a suction system or similar equipment that minimizes airborne dust dispersed in the working environment. These extractors are also known as CPD, or Collective Protection Devices, as fundamental tools in the protection of the health and safety of workers.

Active protection against fine dust: suction walls with integrated filters

Very often you do not want to install a suction system because it “slows down” and goes to interfere with the type of manual work carried out by the operator, that having to use sanding tools on medium-large parts can not rely on suction arms or other mobile systems.

However, there are technical solutions such as suction walls that avoid slowing down the production process, while ensuring high active protection from dust from manual processing for operators and the environment.

In fact, they suck the volatile and inhalable dust thanks to a transverse airflow, suitably dimensioned and in its independent version equipped with integrated filters and extractors represent a valid solution when the client does not want to have a centralized system, perhaps difficult to manage due to the high variability of the workloads.

Suction wall for sanding/grinding WFDThe WFD Sanding/Grinding Suction Wall can be used for the extraction of dust from manual operations, even on large surfaces, grinding, scraps, etc. The production dust is sucked frontally from the wall and through the opposite vertical slats (realized by studying the suction flows), enters a maze that allows the coarsest dust to fall and be collected in the appropriate drawers. The aspirated air then passes through the cartridges mounted on the back that filter it, then rises upwards attracted by the electric fan, and is finally expelled outwards. |

|

Ideal application for active dust protection according to D.Lgs. 81/08

|

As is known to the professionals in particular to each RSPP, art. 15 D.Lgs. 81/08 mentions, among the general measures for the protection of the health and safety of workers in the workplace, the priority of collective protection measures over personal protection measures. This makes dust extraction systems one of the ideal tools for maintaining workplaces that comply with legislations and with the protection of the health and safety of workers.

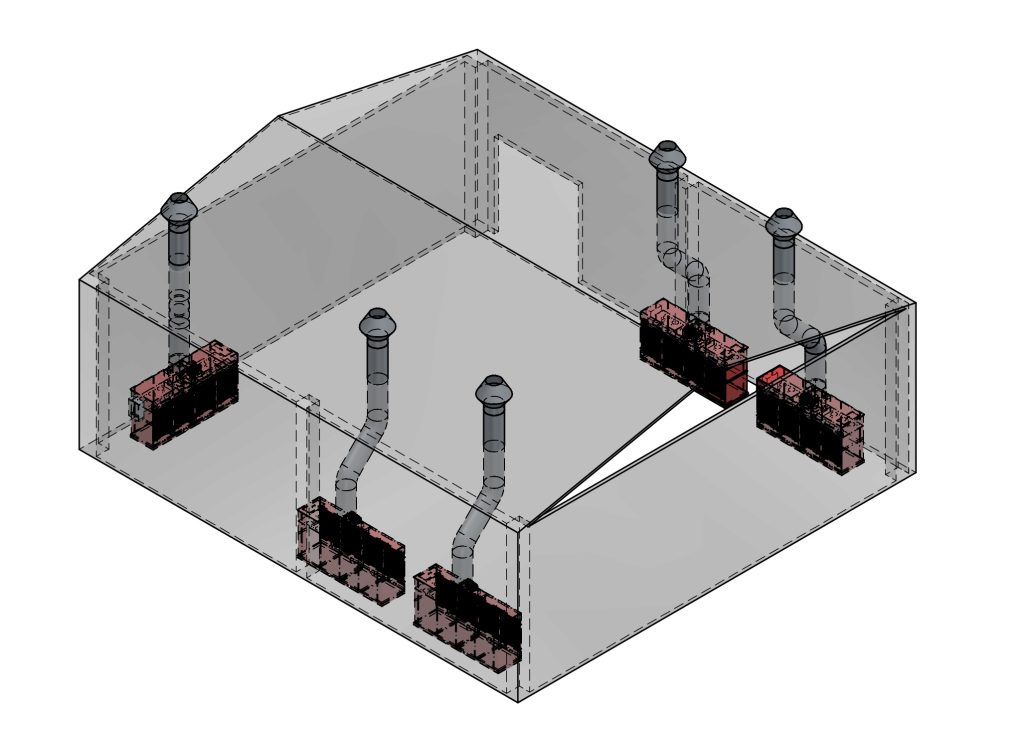

In the 3D project, we see a possible application that uses a series of dust suction walls, in an independent version, complete with fan, filters, and chimney. Otherwise, it is possible to connect the suction walls to a single collector and an external filter. Here you can examine an active dust protection system from manual processing, obtained by installing a centralized suction system. |

Industry 4.0 compliant suction walls

The suction walls of the WFD line are Industry 4.0 compliant in both independent and central systems, thanks to a kit that includes:

- automatic control of the fan revolutions with an inverter, in order to reduce the energy absorption in case the system is poorly used

- control of the degree of clogging filters with real-time reporting of the different thresholds and alarms sent via email to the maintenance service

- remote and optimized management of integrated systems, with warning of any anomalies

- control and signaling anomalies or threshold levels of any sensors accompanying the suction system, such as tribo-metric probes, roto-valves, exhaust augers, or fire sensors