Categories

Pollutants in the form of widespread emissions from presses and molds (such as during hot processing of plastics and rubber) develop mainly as fumes due to the combustion of the material at high temperature in contact with the surrounding air, the harmfulness of which depends on the nature of the materials used.

Unlike localized emissions produced for example by welding or grinding operations at specific points, those of presses and molds are very difficult to capture before they are emitted into the environment because it is not possible to proceed with a close collection system.

For this reason, the exhaust suction systems from presses and molds are in fact tailor-made solutions, normally composed of hoods and infill panels that must not interfere with production and maintenance.

Typical composition of a system for suction fumes from presses and molds

The typical components of a system for the reduction of the diffused emissions from presses and molds is normally composed of:

|  |

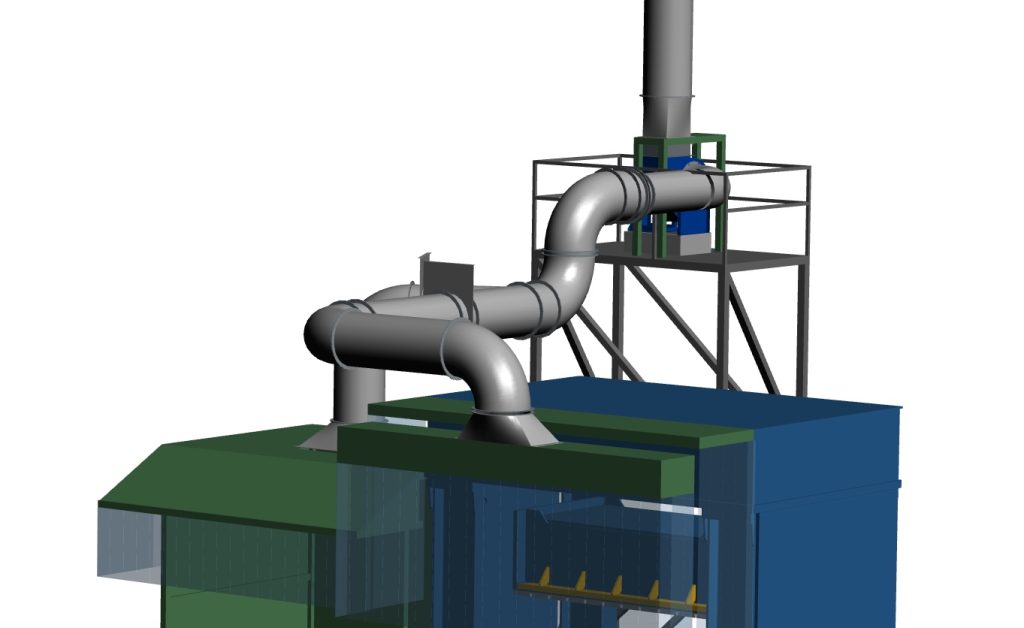

3D design of on-board machine systems

| The suction system for the reduction of chemical risk from emissions spread by presses and molds have made it possible to address the design phase in a rapid and innovative way, confronting from the outset with the dimensions and geometries of the press or production line to be used with the suction system. Every single project step is shared between commissioner and client through the exchange of step files (.STP) eliminating distances, inspections and drastically reducing time and errors. The technical department of Gamma Impianti thanks to the use of a specific parametric software is specialized in 3D design techniques. |

|

Industry 4.0

The suction systems at the service of presses and molds if equipped with filtration are compliant with industry 4.0 thanks to a kit that includes:

- automatic control of the fan revolutions with an inverter, in order to reduce the energy absorption in case the system is poorly used

- control of the degree of clogging filters with real-time reporting of the different thresholds and alarms sent via email to the maintenance service

- remote and optimized management of integrated systems, with warning of any anomalies

- control and signaling anomalies or threshold levels of any sensors accompanying the suction system, such as tribometric probes, roto-valves, exhaust augers, or fire sensors.