Categories

Theindustrial suction system centralized mixed fumes and dust from metal processing is one of the typical situations that our technical office has found itself solving during the years of experience in industrial suction systems.

The design difficulties lie precisely in the fact that it is necessary to aspirate and purify a mix composed of fumes and dust, from different processes such as welding, grinding and polishing; It is therefore necessary to analyze point by point all the processes carried out by the customer during its production process and for each of them to evaluate:

- Type of pollutant collection: for example with suction arm for welding fumes or with suction bench for fumes and grinding powders.

- Required air flow for each different suction point:This parameter also changes a lot depending on the type of equipment used, about 1200/1500 mc/h for arms, 2500/3000 mc/h for 1 benches, 1,5mt long and 4/5000 mc/h for the walls in front of the polishing stations.

- Processing techniques: raw materials and consumable materials used by operators because they can affect a lot by changing the composition of fumes and dust aspirated, resulting in special filtration needs.

- Frequency of use of the various points of the suction system: in practice the contemporaneity of work along the line, so as to properly size the suction fan of the centralized system.

- Finally, it is necessary to evaluate the emission limits in the atmosphere that normally must not exceed 10mg/mc for this type of suction system.

Welding areas

For these lines the problem is solved using self-supporting suction armswith wall mounting and complete with extension that allows a 360 rotation of the arm starting from a distance of 3mt from the wall, In this way the operator can easily position the hood in the point of best suction of the fumes produced.

Column polishers

This processing produces fine powders with low grain size and high volatility, as well as the classic metal residues that fall to the ground. For the extraction of dust which is hazardous to the operator, a cabinet wall in front of machining is positioned in order to exploit the dynamics of rotating tools.

Grinding and sanding manual

If the parts are small and medium size (the plane can be up to 3mt long) the best solution to protect the operator is to suck directly from the plane and the front as seen in video, so dust is not aired in the environment.

This is possible by using a suction bench for fumes and dust, connected to the suction system or independently, equipped with fan and filters on board.

Suction and filtration of pollutants: where is it made?

The characteristic of thecentralized industrial suction system is to convey all the different dangerous pollutants (fumes, dust, exhalations…) in a single industrial purifier usually located outside the building, if possible in the proximity of the fan and chimney of emission into the atmosphere, so as to rationalize the available spaces and simplify maintenance operations.

The purifier used is a cartridge filter made of hydro-antistatic polyester oil repellent specifically used in case of fumes and dust from mixed metal processing.

The long life of the filter cartridges is guaranteed by a fully automated automatic air cleaning system.

Industry 4.0 certified control panel for maximum technical and… administrative performance!

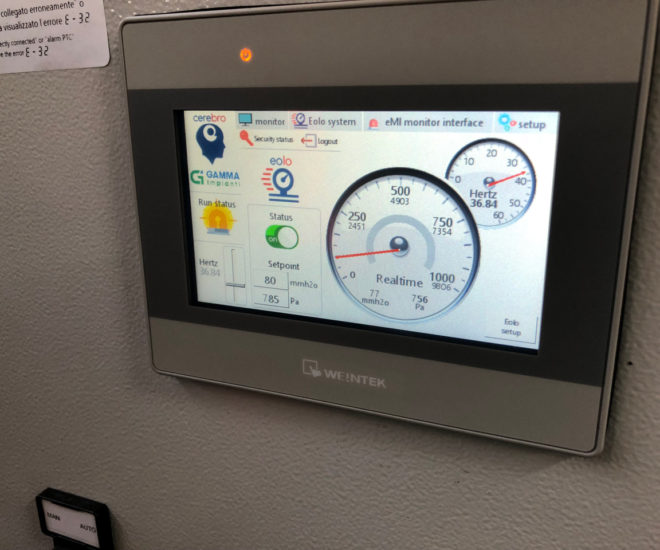

Last but not least, all the vital parameters of the suction system, the alarms and especially the automatic turn control according to the actual use are managed by an electrical panel certified industry 4.0, with huge maintenance advantages and allowing the customer to hyper-amortize the investment to 290% for all 2019.