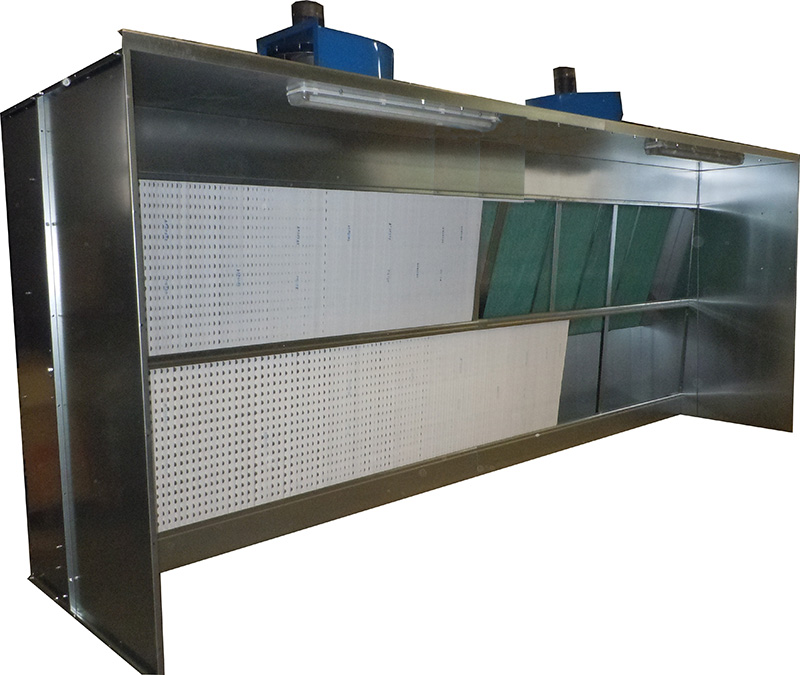

WFP dry spray booth

WFP dry spray booth can be used with chemical solvents or water-based varnishes (not recommended the use of plastic coatings). It is the result of more than 30 years of experience, designed with 3D programmes.

Structure

WPF booth is made of top-quality galavanized sheet iron, worked with numerically controlled punching machine and pressformed by a 6-axis computerized bender. Each panel is trimmed with silicon sealants and bolted together with high-tensile bolts.

The booth is, in fact, an extractor cabinet with a first sloped aspiration level: solution designed to level out aspiration power on the entire frontal surface of the booth.

The real filtering section consists in two stages:

- Strong cardboard with “Brevetto Andreae” any-side holes located in rails and fastened on both sides with screw-down paper clips, which make replacements easy. Binks Andreae cardboard consists in two layers of wrinkled fireproof paper with alternating holes. This design allows air to change direction, so to push paint particles inside towards the second stage of filtration.

- 23mm-thick flat filters made of U-shaped frame in galvanized sheet metal, two containment nets of electrowelded galvanized steel and a progressive density fiberglass filter media with 200 gr/m2 weight.

The fan is located in the upper part of the booth, resting on swivel fittings and mounting bracket. Those, have been specifically designed for our WPF cabinet to bear enough weight and a 7-12mt exhaust line, average lenght in extraction plants. The high-performance backward curved electric fanis the ideal solution for high flow rate environments. It is mostrly used for suction of clean, slightly dusty air and air with traces of varnish particles.

WPF boothsinclude electrofan of varnished carbon steel, directly paired to a three-phase engine with backward shovel impeller statically and dynamically balanced to prevent vibrations, so to grant a longer life to engine’s ball bearings.

Electrical panel provided in plastic boxe with start and stop button and lighting control. The panel also includes a magnetothermic adjustable protection and EMS emergency. Its installation foresees inlets and sockets to connect between them panel, fan and lighting. A 3mt cable is provided with 220V and 380V plugs.

Warning!This system doesn’t need a professional installation. It is enough to connect power, verify the direction of air flow and your booth is ready to work.

Ask a quotation or contact us

Associate systems

Those who have already chosen us...