Mobile welding fumes extractor

Welding fumes and dust are toxic, protect yourself

Welding fumes and dust must be extracted paying special attention to the kind of work the operator has to execute, hence his/her position in relation to the machine. Any mobile welding fumes extractor should take into account this fundamental parameter, so to extract fumes close enough to the source with its self-supported suction arm.

Watch our mobile welding fumes extractor at work:

It is imperative to use mobile welding fumes extractor designed in compliance with the reference regulations (D.Lgs 81/08).

Legislative decree no.81, April 9th 2008 (a. IV p. 2.1.5)

Aspiration of gas, steams, odour and fumes must take place as close as possible to their source. Occupational exposure limits lays down concentration thresholds which cannot be exceeded in the air breathed by operators. Those values derives from scientific data provided by the Board of Health, with the aim to limit presence of powders within working environments.

Occupational exposure limits must be respected according to each element composing welding fumes.

SPECIAL WEB PROMOTION: read more about it!

Mobile welding fumes extractor purifies air from fumes, dust and gases containings dozens of harmful chemicals. Those remain in the environment as micro-powders, metal particles or metal derivatives (as oxides) and filler metals (as electrodes, rod electrodes, lead, welding powder, etc.), or they are removed later by coatings as varnish, upholstery and detergent.

Our efficient and low-budget solution

Welding fumes extractor MFU can be easily moved where it’s needed thanks to compact size, wheels and convenient handlings. Once there, it aspires fumes through its self-supporting suction arm ending in a hood with handling, to extract emission straight from the source.

ADVANTAGES

- Quick: fumes suction straight from the source thanks to a high flow rate.

- Mobile: it can reach many welding working spots.

- Filtration: with absolute filter H13 ≥99.95%.

- In compliance with CE norms.

| How the mobile purifier works

MFU16 aspires pollutants from a flexible pipe or a suction arm. Then, pollutants are filtered to 99,95% of efficiency while crossing the purifier towards the bottom. Finally, any odour is absorbed by active carbons. Environment safety Level of clogging is constantly monitored by a system with a led signal, which advise when it is necessary to clean or substitute filters. Easy to use Its light 3 mt. suction arm with hood, handling and flexible pipes can be moved effortless. |

|

Technical data

Rated capacity 1.500 mc/h

Engine power 1,5kW 220/1/50

Total weight 110 kg ca

Filtration:

Stage 1 – sparkproof metallic filter G3

Stage 2 – acrylic filter G4 (following EN 779:2012)

Stage 3 – absolute filter H13 ≥99.95% (@ MPPS following EN 1822:2009)

Stage 4 – active carbons filter for odours

Structure

Supporting structure of strong galvanised or powder-coated iron, with practical handles and 4 pivoting wheels with brake.

Electrical panel in accordance with CE rules, with on/off switch for ventilation and warning led for filter clogging.

Centrifugal fan with simple inlet, directly paired to asynchronous single-phase motor.

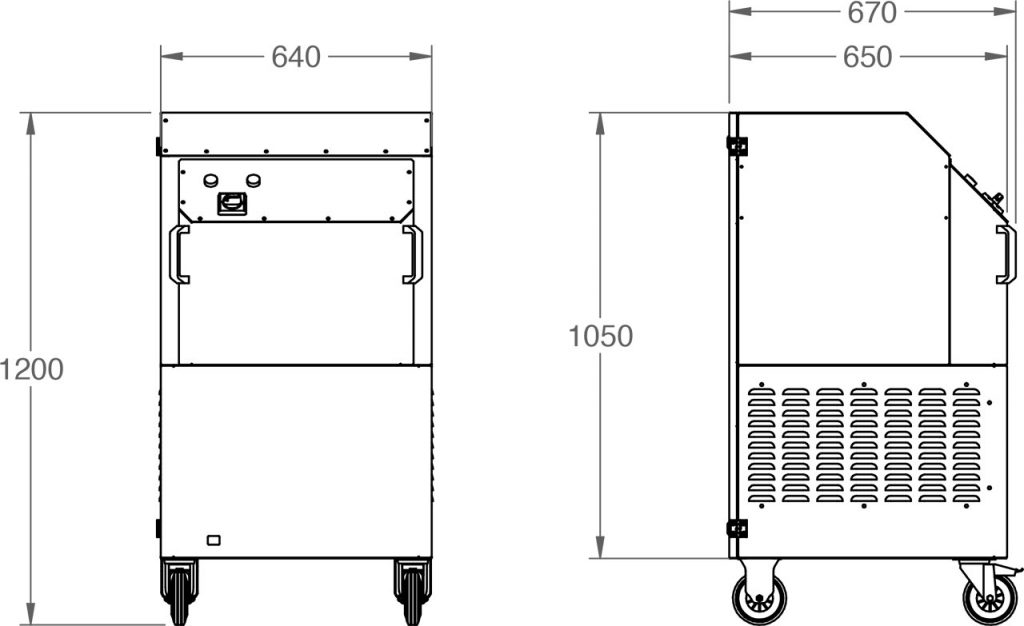

Size

sectors of application

MetalworkAssociate systems

4.0 extraction systems

Welding fumes extraction

Aspiration for grinding

Extraction on the machine

Extraction for varnishing

Chip extraction

Noise treatment

Clean rooms

Temperature and humidity control

Air conditioning and heating

Ask a quotation or contact us

Those who have already chosen us...