Air purifier for smokes and steams from annealing furnace

Environmental problem

Draining and annealing furnaces employed in goldsmith workshops produce smokes and fumes coming out from the top of the furnace, where there is an opening to allow their evacuation.

Normally, goldsmith workshops are not big enough to host complex plants with pipes ejecting air outside.

Solution

Mobile air purifier MFU16 was designed by Gamma impianti to vacuum and filter fumes, steams and microdusts due to annealing processes in goldworking, mechanical production processes and precious metal working. Fumes and steams are sucted from a hood on a 2 or 3 mt suction arm. Alternatives available: flexible pipes and special hoods.

ADVANTAGES

- Quick: fumes suction straight from the source thanks to high flow rate.

- Mobile and compact: it can be employed in every workshop or studio.

- Smokes filtration with absolute filter H13 ≥99.95% and odours filtration with active carbons.

- 1500W single-phase power, suitable for Shuko outlet.

| How the mobile purifier works

MFU16 aspires pollutants from a flexible pipe or a suction arm. Then, pollutants are filtered at 99,95% of efficiency while crossing the purifier towards the bottom. Finally, odours are absorbed by active carbons. Environment safety Level of clogging is constantly monitored by a system with led signal, which advise when it is necessary to clean or substitute filters. |

|

Technical data

Rated capacity 1.500 mc/h

Engine power 1,5kW 220/1/50

Total weight 110 kg ca

Filtration:

Stage 1 – sparkproof metallic filter G3

Stage 2 – acrylic filter G4 (following EN 779:2012)

Stage 3 – absolute filter H13 ≥99.95% (@ MPPS following EN 1822:2009)

Stage 4 – active carbons filter for odours

Structure

- Supporting structure of strong galvanised or powder-coated iron, with practical handles and 4 pivoting wheels with brake.

- Electrical panel in accordance with CE norms, with on/off switch for ventilation and warning led for filter clogging.

- Centrifugal fan with simple inlet, directly paired to asynchronous single-phase engine.

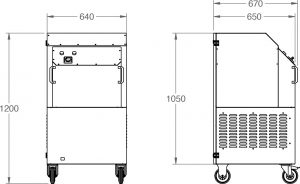

Size

sectors of application

Machinery and production linesAssociate systems

4.0 extraction systems

Welding fumes extraction

Aspiration for grinding

Extraction on the machine

Extraction for varnishing

Chip extraction

Noise treatment

Clean rooms

Temperature and humidity control

Air conditioning and heating

Ask a quotation or contact us

Those who have already chosen us...